- MK 24

- MK 48

- MK 100

AREAS OF APPLICATION:

- Outdoor swimming pools private / public

- Indoor swimming pools, private / public

- Theraphy pools

- Whirlpools

The electrolyzer is connected to the pool water and does not require a fresh water connection. Part of the pool water is used to absorb the disinfectant produced, which is fed into the circulation line by means of an injector. This means that no additional dosing pump is required.

The suction is monitored and if the quantity falls below a minimum level, production is switched off. Due to the arrangement of the cell under water, there is no danger from escaping chlorine. In addition, there is an optional chlorine gas sensor for monitoring the room air. The system can be mounted using the optionally available wall brackets and the salt dissolving tank placed underneath. This means that the space requirement is low and installation is simple.

- MI 250

- MI 500

AREAS OF APPLICATION:

- Public outdoor swimming pools

- Public indoor swimming pools

- School swimming pools

- Therapy pools

The electrolysis system is connected to fresh water and to the pool water. The pool water is used to absorb the disinfectant produced, which is fed into the circulation line by means of an injector. This means that no additional dosing pump is required.

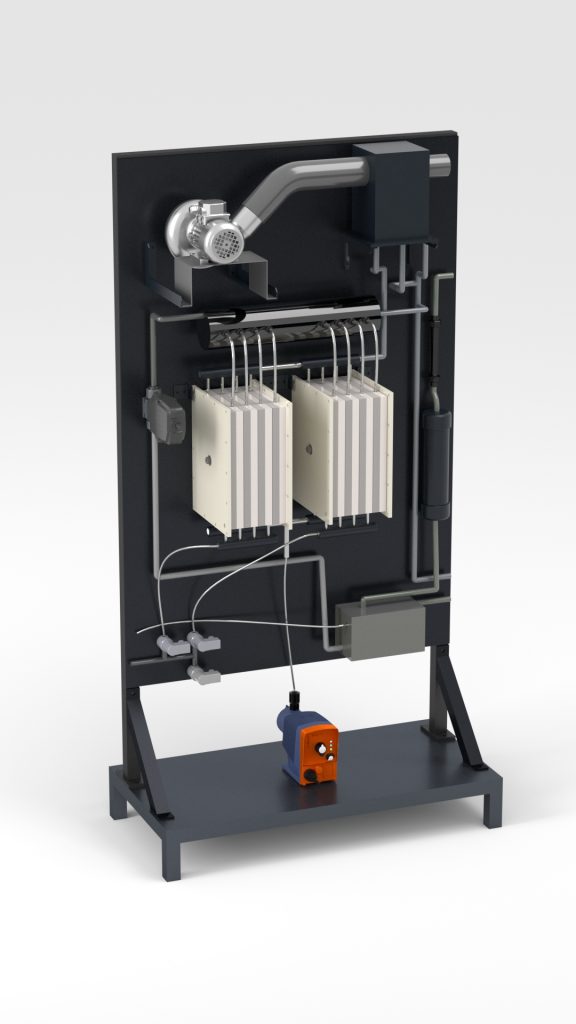

The extraction is monitored and production is switched off if the quantity falls below a minimum level. The fresh water is used exclusively for production and is softened to a value between 0 and 1° dH by means of an independent softener. A pressure reducer reduces the upstream pressure of the fresh water to 1 bar and ensures constant conditions inside the electrolysis cell. The system is pre-assembled on a free-standing frame. This considerably reduces the installation work on site. For safe operation of the plant, it has a pre-installed chlorine gas sensor. The hydrogen produced in the cathode chamber is discharged to the outside. (for type 200 by means of a fan)

- ECO-a

- ECO-a 20/40/75/90 Kompakt

- ECO-a 75/90/150/200/300/500

- ECO-a 1000/2000/4000

AREAS OF APPLICATION:

- Public outdoor swimming pools

- Public indoor swimming pools

The ECO-a series

Our new ECO-a series offers many advantages of our previous systems paired with new developments and improvements around the use in swimming pools.

Especially the advantage of positioning the salt and product tank independently from the system allows maximum user-friendliness in planning and operation of your swimming pool.

The integrated control regulates the power and monitors all operating parameters. The hydrogen produced during the process is separated by a degassing tank and must be discharged to the outside.

The fresh sodium hypochlorite enters the product tank without an additional pump and can be metered from there as required.

ECO-a 20/40/75/90 Kompakt

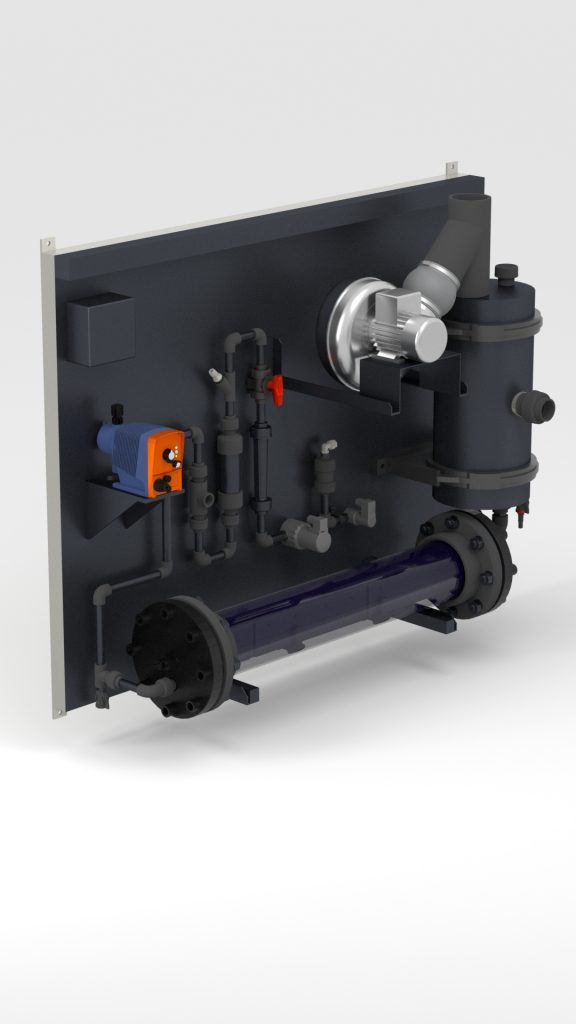

The units are mounted on a PVC plate and are mounted on the wall.

The tubular cell is operated with a fixed salt concentration and are ideal for small to medium private and hotel pools.

In-situ production of aqueous sodium hypochlorite ensures maximum disinfection effect with minimum chlorate formation. The undivided cells have a long service life and are deliberately kept simple.

ECO-a 75/90/150/200/300/500

The units are mounted on a powder-coated stainless steel frame and are suitable for wall mounting as well as for free-standing installation.

The control cabinet is mounted on the plant ( except ECO-a 500 ) and the integrated PLC control monitors and controls all relevant operating parameters and has numerous connection options such as external enable On/Off, Modbus IP and Modbus RS485.

The salt concentration in the inlet of the tubular cell electrolysis is continuously measured and controlled. Due to the additional temperature monitoring, a low-chlorate sodium hypochlorite solution is thus produced directly on site.

The undivided cells have a long service life and are deliberately kept simple.

ECO-a 1000/2000/4000

The units are mounted on a free-standing frame, allowing flexible installation. The salt and product tank can be positioned independently of the plant.

The control cabinet for wall mounting can be freely placed near the plant and the integrated PLC control monitors and regulates all relevant operating parameters and has numerous connection options such as external enable On/Off, Modbus IP and Modbus RS485.

The salt concentration in the inlet of the tubular cell electrolysis is continuously measured and controlled. Due to the additional temperature monitoring, a low-chlorate sodium hypochlorite solution is thus produced directly on site.

The undivided cells have a long service life and are deliberately kept simple.